Warn Off-Road Winch Fairlead

$48.95

EVERYTHING IS FREE SHIPPING

As Low As 0% Up To 24 Months, Visit Financing Options!

Vehicle Product Fitment Listed Below

In Stock Item (See Below Shipping Tab)

Purchasing Earns $2.45 In Cash Back Rewards

Factor 55 Off-Road Fairlead

This ATV Winch Fairlead Is CNC-Machined From 1″ Thick USA 6000 Series Aluminum. Hard-Anodized Finished. Perfect With Synthetic Winch Line.

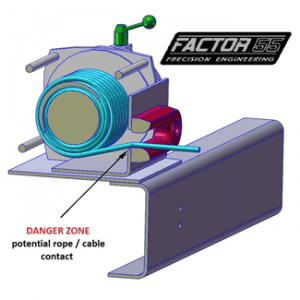

Factor 55 introduces a new line of Aluminum Hawse Fairleads for the Powersports UTV/ATV market. Offered in the common 4.875″ mounting bolt spacing for Powersport UTV/ATV winches.

The 4.875″ fairleads are CNC machined from 1 inch thick USA 6000 series aluminum bar. The industry standard fairlead thickness is .50 inches thick.

The thicker aluminum bar results in a larger outer fillet radius for the synthetic rope to slide against. This results in less stress on the rope fibers during high angular pulls, increasing the life of your synthetic rope.

These fairleads come in a durable MIL-A-8625F TYPE III gun metal gray hard anodized finish with a laser engraved logo.

Mount Bolt Hole Spread: 4.875″

Overall Dimension: 6.25″ x 1.95″

Note: For synthetic winch rope only. Does not come with mounting hardware (uses winch hardware).

MADE IN THE USA

What is the best surface finish for Hawse aluminum fairleads?

Without a doubt it is a Type III hard anodized coating.

A hard coating can resist the abrasion damage from a dirty/gritty synthetic winch rope rubbing across it.

Especially during extreme side pulls where rope fiber stresses are extremely high.

A Mil-A-8625 Type III hard anodized finish leaves a .002” thick Al2O3 ceramic coating that is in the top 5 hardest materials known to mankind.

Not too far away from diamond hardness actually. Another valuable material property from hard anodized coatings are the low coefficients of friction. Low friction = lower rope heat.

Only drawback? Hard anodizing is not offered in typical bright and fancy anodized colors. All Factor 55 fairleads only come in Mil-A-8625 hard gray finishes. Not fancy, but it is the proper finish to extend the life of your synthetic rope.

About Factor 55

Factor 55 products are designed and manufactured using state of the art technologies.

All of our products are designed and then stress analyzed, resulting in us to optimize a design concept by adding or removing material or changing material properties where necessary.

We then validate our theoretical results by instrumenting and destructively testing prototypes of all of our product designs.

This is conducted at a test and measurement facility that is also certified for National Defense Department rigging and hoist testing.

At Factor 55 we don’t believe in engineering compromises. That’s why we produce all of our products from aerospace quality materials.

From 6000 and 7000 series aluminums, to 6AL-4V titanium double shear pins, we strive to offer you the very best designs made from the ve

In Stock Items:

Any In Stock items will be shipped within 24-36 hours of order processing Monday through Friday, orders placed on Saturday or Sunday will be processed Monday.

When Your items are Picked Up By The Shipper Our System will Updated and Email You Tracking.

Powder Coated / Custom Colors / Fabrication ORDER PROCESSING

Please allow adequate time for custom fabrication parts to be built, powder coated, and shipped. Currently These Items Are 8-12 Business Days for Production

Lead Times define the maximum estimated amount of time required to prepare the item for shipping and may vary depending on product, volume of current orders, and/or build schedules. This includes fabrication, powder coating, packaging, and other preparation. In the event that Lead Times are delayed you will be contacted via email or phone call.

Lead Times DO NOT include shipping transit times.

All parts will be shipped as soon as possible after the initial Lead Time using your selected shipping method.

Bolt Spread: 4.875″

Overall Dimension: 6.25″ x 1.95″

| Make | Model | Year |

|---|---|---|

| All Universal Fitment | ATV Machine - Universal Fitment | |

| All Universal Fitment | UTV Machine - Universal Fitment |

You may also like…

ATV PRODUCTS

ATV WINCH

What others are saying

There are no contributions yet.