High Lifter Can-Am Defender Portals, Dual Idler

From: $3,954.99

High Lifter Can-Am Defender Portals, Dual Idler

From: $3,954.99

High Lifter Can-Am Defender Portals, Dual Idler

From: $3,954.99

ALWAYS FREE SHIPPING

As Low As 0% Up To 24 Months, Visit Financing Options!

Vehicle Product Fitment Listed Below

High Lifter Dual Idler Portals For Defender Models

This High Lifter Can-Am Defender Portals, Defeneder Suspension Gear Lift is made tough and ready for any challenge. Now engineered with a gearing setup that allows two idler gears in the portal box to spread the load between twice as many teeth on the gears.

This doubles the area and reduces the stress by half, allowing more abuse. This kit is for riders who are looking for torque and power.

High Lifter is the first company to offer a dual idler gear reduction. This spreads the load across two sets of idles, and makes for a more reliable, responsive UTV portal lift.

To build some of the longest-lasting kits around, choosing a forged gearbox eliminates the occurrence of porosity and cavities that reduce the strength of a part.

What does the Dual Idler Gear Lift offer?

- High Lifter improved the portal design by adding a second idler gear in the gear box

- The dual idler gears spread the load over twice as many teeth on the gear sets, which doubles the area and reduces stress by half.

- You gain more reliable torque transfer

- Stop burning up belts and breaking so many axles; differentials; drive shafts; snorkel gears…

- Gear reduction extends brake life by needing brakes less often due to greatly improved engine braking

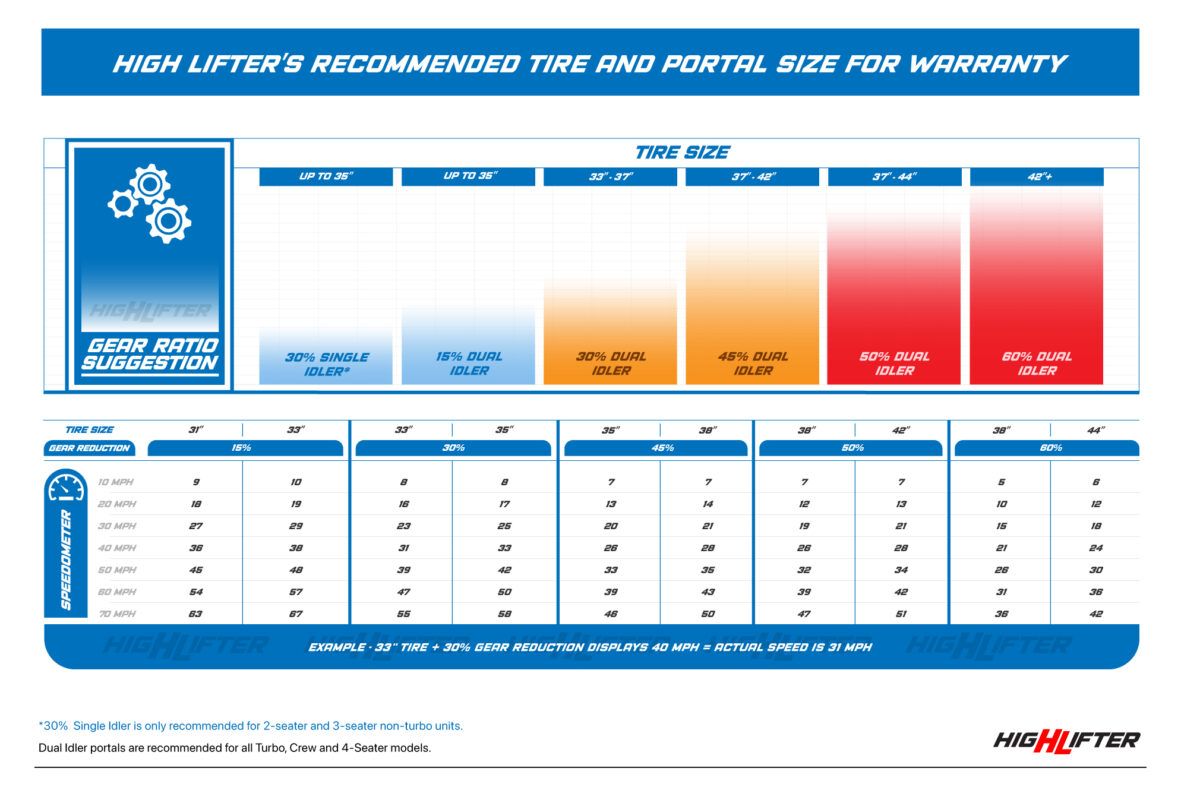

- Even though a lower gear ratio will get your speedometer closer to a stock reading, that is still too high a gear to offset the loss of torque caused by the larger tires. If you don’t have a need to run fast, a lower ratio performs better and give you the power you want!

Why Highlifter Portals:

Forged Gear Boxes

- Strongest boxes on the market because forging produces a tougher piece of metal

- Forging is stronger than both cast and billet aluminum

- Competitors use cast aluminum and billet aluminum boxes

- These portal boxes are extremely robust and give you more worry-free miles than any other portal

Gear Box Venting

- Customers asked for box venting and we give you the option

- Our box design offers a plug for venting with an optional easy to install kit that will be available soon

- Vent kits allow an advantage of cooling which reduces early deterioration of the gaskets and seals

Gasket Material and Design

- High density Kevlar fiber gaskets plus no additional sealant is needed

- Gasket material is creep resistant plus oil and coolant resistant

Seals

- Two oil seals on the spindle shaft for 100% more sealing area

- Dual seals prevent water intrusion and oil leaks

- True triple seal on the input shaft which includes a wiper seal that provides a significant extra layer of protection

Backing Plate

- These are the strongest backing plates on the market

- 5/16” steel plate with Bent flanges for strength and durability Okay

- Welded gusset brackets and designed to factory off-set

- Works with all control arms that are built to factory hub specifications

Rotors

- Precision ground Stainless Steel rotors (this is a big deal for brake performance)

- Access holes for ease of assembly and disassembly

- Slotted rotor allows for heat dissipation and cooling

Gear Profile

- Alloy steel heat treating process increases overall internal and external strength

- CNC precision ground machining ensures excellent fitment and increased strength

- Controlled gear lapping for ease of installation and a quieter performance

Wheel Requirements 4″ Portals:

14″ or larger

14″ factory wheels must run 1″ spacer

14″ & 15″ can not exceed 4-1/2″ backspacing

16″ & larger can not exceed 5″ backspacing

Wheel Requirements 6″ Portals:

18″ or larger wheel required • Up to 30″ Stock

18″ wheels cannot exceed 4-1/2″ backspacing • 31″ with 3″ Lift Kit

20″ and larger wheels cannot exceed 5″ backspacing

Wheel Requirements 8″ Portals:

22″ or larger wheel required

22″ and larger wheels cannot exceed 5″ backspacing

Manuals

4" Install 2016-2021 Guide

Download Document4" Install 2022 Newer Guide

Download Document6" Install 2016-2021 Guide

Download Document6" Install 2022 Newer Guide

Download Document8" Install 2016-2021 Guide

Download Document8" Install 2022 Newer Guide

Download DocumentHigh Lifter offers a Limited Lifetime Warranty to the original purchaser that our product shall be free from defects in material and workmanship for the life of the product if utilized in accordance with the manufacturer’s instructions for installation and operation of said products. This Limited Lifetime Warranty extends to the following product lines:

• Lift Kits (Signature, Standard and Big Lifts)

• Control Arms

• Trailing Arms

• Radiator Relocation Kits

• Portal Gear Lifts

• Wheel Spacers

• Tow Hooks

• Control Arm Link Kits

For Complete Warranty Information And Claims Information Please Click “High Lifter Warranty”

IN STOCK PARTS – Any items in current inventory we ship within 36-48 hours after order.

- Portal Gears Can Take Up To 7-10 Business days To Ship After Order because of Assembly.

- Snokel Kits Can Take Up To 7-10 Business days To Ship After Order because of Assembly.

- Pressed In Ball Joint Arm Orders Cake Up To 7-10 Business days To Ship After Order because of Assembly.

We currently only ship Monday through Friday, if you place the order over the weekend we will process it on Monday.

Current Fabrication or Production Run Parts

Currently anything listed on the site is traditionally stocked and ready to ship but there are times that we are currently in a production run and or waiting for powder coating, this could result in 10-14 Business day shipping

Lead Times define the maximum estimated amount of time required to prepare the item for shipping and may vary depending on product, volume of current orders, and/or build schedules. This includes fabrication, powder coating, packaging, and other preparation. In the event that Lead Times are delayed you will be contacted via email or phone call.

Lead Times DO NOT include shipping transit times.

All parts will be shipped as soon as possible after the initial Lead Time using your selected shipping method.

| Make | Model | Year |

|---|---|---|

| Can-Am Off Road | Defender DPS CAB HD9 | 2022 Defender DPS CAB HD9 - 2025 Defender DPS CAB HD9 |

| Can-Am Off Road | Defender DPS HD10 | 2016 Defender DPS HD10 - 2025 Defender DPS HD10 |

| Can-Am Off Road | Defender DPS HD7 | 2022 Defender DPS HD7 - 2025 Defender DPS HD7 |

| Can-Am Off Road | Defender DPS HD8 | 2016 Defender DPS HD8 - 2021 Defender DPS HD8 |

| Can-Am Off Road | Defender DPS HD9 | 2022 Defender DPS HD9 - 2025 Defender DPS HD9 |

| Can-Am Off Road | Defender HD10 | 2016 Defender HD10 - 2021 Defender HD10 |

| Can-Am Off Road | Defender HD7 | 2022 Defender HD7 - 2025 Defender HD7 |

| Can-Am Off Road | Defender HD8 | 2016 Defender HD8 - 2021 Defender HD8 |

| Can-Am Off Road | Defender HD9 | 2022 Defender HD9 - 2025 Defender HD9 |

| Can-Am Off Road | Defender Limited HD10 | 2020 Defender Limited HD10 - 2025 Defender Limited HD10 |

| Can-Am Off Road | Defender MAX DPS HD10 | 2017 Defender MAX DPS HD10 - 2025 Defender MAX DPS HD10 |

| Can-Am Off Road | Defender MAX DPS HD7 | 2024 Defender MAX DPS HD7 - 2025 Defender MAX DPS HD7 |

| Can-Am Off Road | Defender MAX DPS HD8 | 2017 Defender MAX DPS HD8 - 2021 Defender MAX DPS HD8 |

| Can-Am Off Road | Defender MAX DPS HD9 | 2022 Defender MAX DPS HD9 - 2025 Defender MAX DPS HD9 |

| Can-Am Off Road | Defender MAX HD7 | 2022 Defender MAX HD7 - 2025 Defender MAX HD7 |

| Can-Am Off Road | Defender MAX HD8 | 2019 Defender MAX HD8 - 2021 Defender MAX HD8 |

| Can-Am Off Road | Defender MAX HD9 | 2022 Defender MAX HD9 - 2025 Defender MAX HD9 |

| Can-Am Off Road | Defender MAX Limited | 2022 Defender MAX Limited - 2025 Defender MAX Limited |

| Can-Am Off Road | Defender MAX Lonestar | 2018 Defender MAX Lonestar - 2025 Defender MAX Lonestar |

| Can-Am Off Road | Defender MAX X MR | 2019 Defender MAX X MR - 2025 Defender MAX X MR |

| Can-Am Off Road | Defender MAX XT CAB HD10 | 2018 Defender MAX XT CAB HD10 - 2021 Defender MAX XT CAB HD10 |

| Can-Am Off Road | Defender MAX XT HD10 | 2017 Defender MAX XT HD10 - 2025 Defender MAX XT HD10 |

| Can-Am Off Road | Defender MAX XT HD8 | 2017 Defender MAX XT HD8 - 2021 Defender MAX XT HD8 |

| Can-Am Off Road | Defender MAX XT HD9 | 2022 Defender MAX XT HD9 - 2025 Defender MAX XT HD9 |

| Can-Am Off Road | Defender PRO | 2020 Defender PRO - 2021 Defender PRO |

| Can-Am Off Road | Defender Pro DPS | 2022 Defender Pro DPS - 2025 Defender Pro DPS |

| Can-Am Off Road | Defender Pro Limited | 2022 Defender Pro Limited - 2025 Defender Pro Limited |

| Can-Am Off Road | Defender Pro Lone Star | 2022 Defender Pro Lone Star |

| Can-Am Off Road | Defender Pro XT | 2022 Defender Pro XT - 2025 Defender Pro XT |

| Can-Am Off Road | Defender X MR HD10 | 2018 Defender X MR HD10 - 2025 Defender X MR HD10 |

| Can-Am Off Road | Defender XT CAB HD10 | 2019 Defender XT CAB HD10 - 2021 Defender XT CAB HD10 |

| Can-Am Off Road | Defender XT CAB HD8 | 2019 Defender XT CAB HD8 - 2021 Defender XT CAB HD8 |

| Can-Am Off Road | Defender XT HD10 | 2018 Defender XT HD10 - 2025 Defender XT HD10 |

| Can-Am Off Road | Defender XT HD7 | 2024 Defender XT HD7 - 2025 Defender XT HD7 |

| Can-Am Off Road | Defender XT HD8 | 2018 Defender XT HD8 - 2021 Defender XT HD8 |

| Can-Am Off Road | Defender XT HD9 | 2022 Defender XT HD9 - 2025 Defender XT HD9 |

| Can-Am Off Road | Defender XT-P HD10 | 2019 Defender XT-P HD10 - 2021 Defender XT-P HD10 |

You may also like…

UTV Ball Joints

UTV Arm Link Bars

UTV Lift Kits

What others are saying

There are no contributions yet.