Trinity Racing Can-Am Maverick R Exhaust

$1,329.99

EVERYTHING IS FREE SHIPPING

As Low As 0% Up To 24 Months, Visit Financing Options!

Vehicle Product Fitment Listed Below

In Stock Item (See Below Shipping Tab)

Purchasing Earns $66.50 In Cash Back Rewards

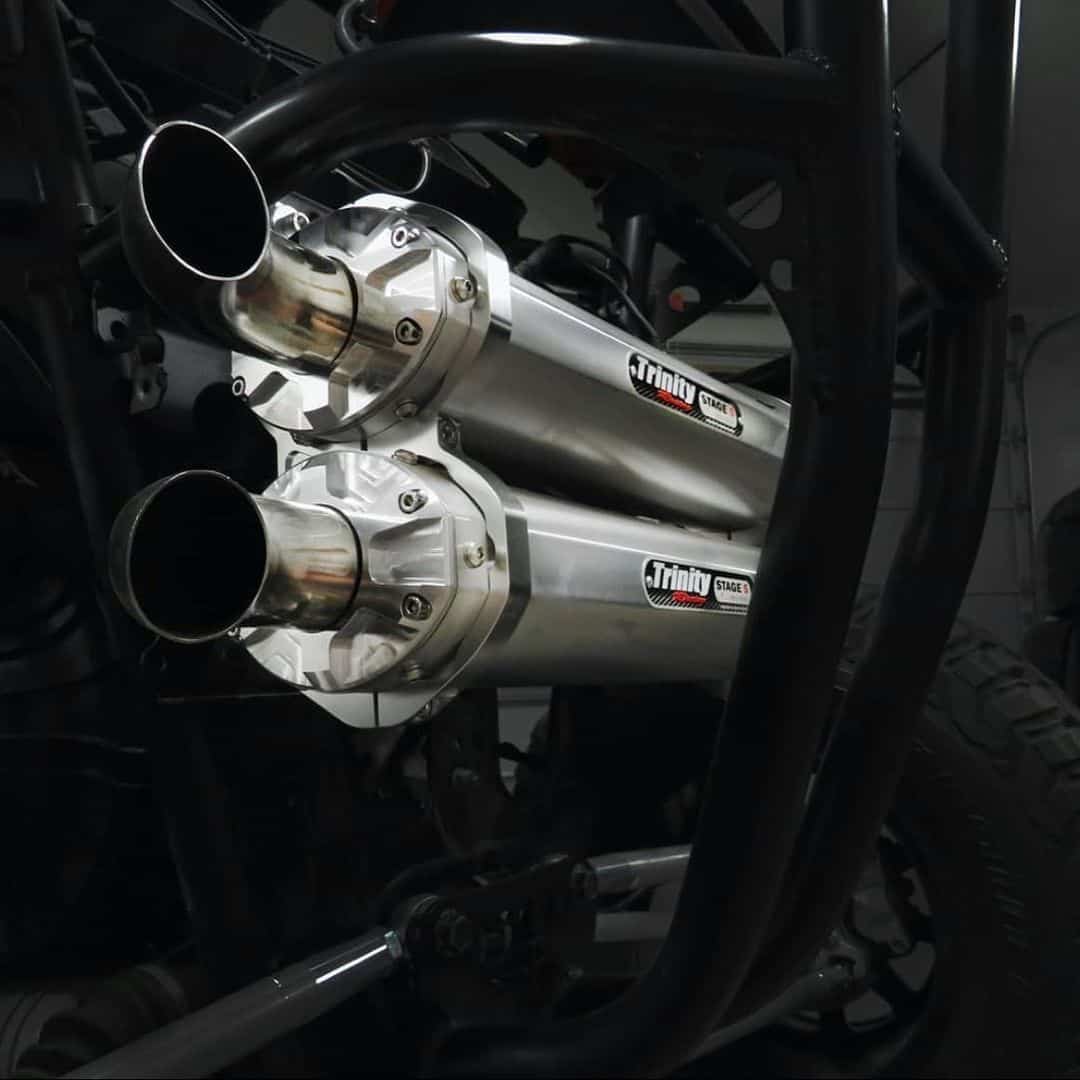

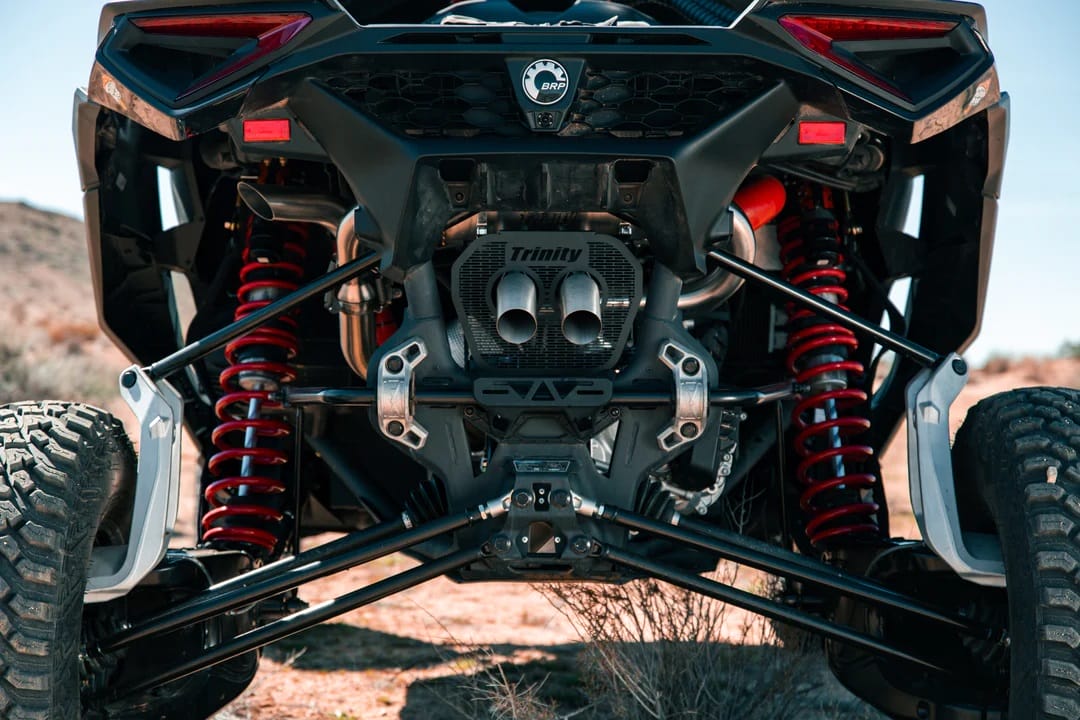

Trinity Racing Slip On Muffler for Maverick R Models

Trinity Racing Can Am Maverick R Exhaust. Slip On Muffler Slip On Design. Stainless Steel Tig Welded Perforated Baffle. Billet Aluminum Exhaust And Pipe Options.

Comes Stainless Steel, Tig Welded, Will Reuse OEM Tip If You Choose No Tip.

Looking To increase Performance while lowering drag,

This is a fully Made in America System Tig Welded to perfection and created for all riders.

Slip on system that is exhaust and mufflers, Your OEM Exhaust Tip Will Mount To This.

Comes with Spark Arrestors, Mounting Brackets and Hardware and Trinity Name Plate.

Easy Install With Everything Needed Included

Features:

- 304 brushed stainless steel exhaust

- 14″ Single stainless steel muffler in a brushed finish

- Fully Tig Welded

- Mounts to stock or aftermarket header

- Significant horsepower and torque gains

- Light Weight Design

- 2 year warranty

- Made in the USA

- Limited Increase In DB’s Compared To Stock, with more growel

Add On Options

High Flow Standard Head Pipe

- Replacement header pipe for Can-Am Maverick R

- Allows for the removal of the catalytic converter, while retaining the stock muffler for testing purposes

- Also fits with Aftermarket Slip-on Mufflers

- Direct bolt on system

- 304 Stainless Steel

- Fully Tig Welded

- Oxygen sensor bung

- Significant horsepower and torque gains

- 2 year warranty

- Made in the USA

ELECTRONIC CUTOUT Head Pipe

The electronic cutout allows you to change the sound of your exhaust with the flick of a switch

- All necessary parts to mount onto your vehicle

- Header Flange

- Wiring harness and custom Trinity switch

- Electronic Valve, welded directly to header pipe

- Stainless Steel turn out pipe

- Crushable Cometic gasket for muffler to header

- Made of 304 Stainless Steel

- Hand TIG welded in the USA

About Trinity Racing

Trinity Racing has been offering products that create horsepower for the offroad industry since 1978. With 41 Years of incredible success our new sole focus is to manufacture top quality exhaust systems and complimentary components for the ATV and UTV industry.In our California based state of the art manufacturing facility which includes CNC Bending, Tig Welding, CNC Machining, Laser Cutting/Etching we have the ability to design, fabricate, machine, and test the best performing systems available.

These Come With a 2 Year Warranty and We follow all Trinity Racing Warranty Polices.

Warranty Claim Form Located – “HERE”

In stock Items – These items ship within 24 – 36 hours after order time Monday Through Friday. Orders Places on Friday through the weekend will start to process Monday Morning.

Holidays Start processing The first day back.

Certain Exhausts: Currently all parts are in Stock but could take up to 7-10 business days to ship because the systems need to be assembled, packed and shipped.

Production Run Items – These traditionally ship 2-3 weeks after order, we recommend placing the order and the moment they are available we will ship them directly to you for speed.

| Make | Model | Year |

|---|---|---|

| Can-Am Off Road | Maverick R | 2024 Maverick R - 2026 Maverick R |

You may also like…

UTV PRODUCTS

UTV Exhausts

What others are saying

There are no contributions yet.