Gates CFMOTO UForce 600 Belt, CVT Upgrade Redline

Gates CFMOTO UForce 600 Belt, CVT Upgrade Redline

Gates CFMOTO UForce 600 Belt, CVT Upgrade Redline

$205.99 Original price was: $205.99.$184.99Current price is: $184.99.

EVERYTHING IS FREE SHIPPING

As Low As 0% Up To 24 Months, Visit Financing Options!

Vehicle Product Fitment Listed Below

In Stock Item (See Below Shipping Tab)

Purchasing Earns $9.25 In Cash Back Rewards

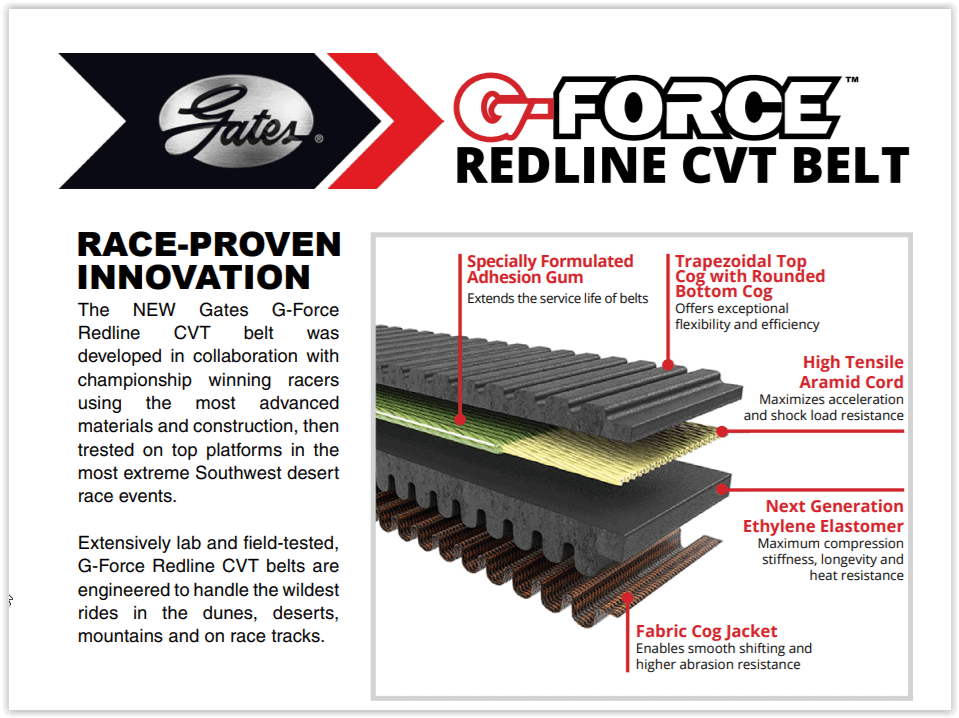

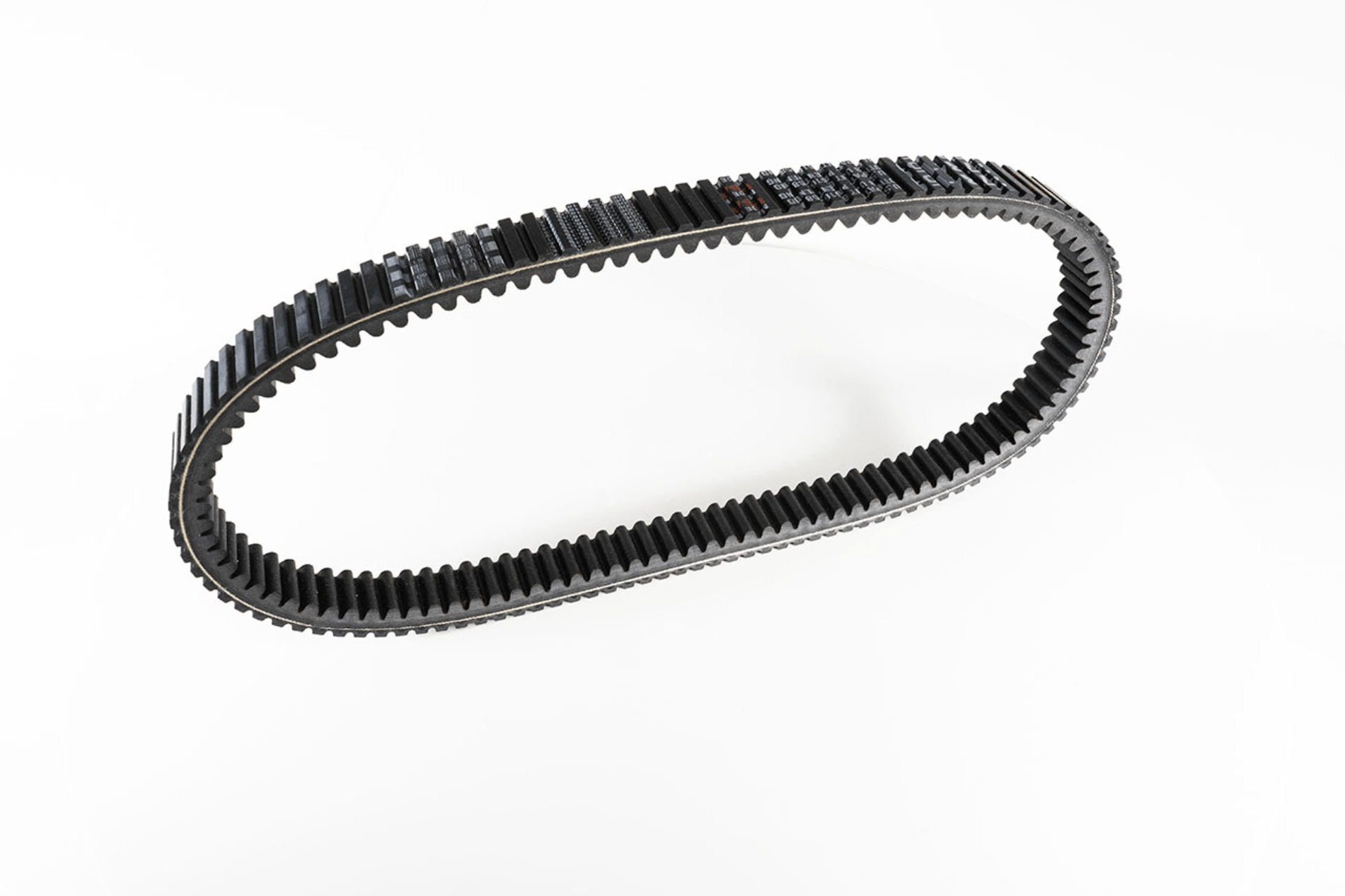

Gates G-Force Performance Redline CVT Belt For UForce 600 Models.

Patented EE Compound Maximizes Axial Stiffness Enabling Belts To Run At Higher Continuous Torques. The Gates Redline UForce 600 Belt Takes All The Heat

Patented EE Compound Maximizes Axial Stiffness Enabling Belts to Run at Higher Continuous Torques. The Gates Redline RZR Turbo R Belt Takes All The Heat

Designed for the most demanding, ATV and UTV applications. With Gates proprietary materials and design, G-Force RedLine™ CVT UForce 600 belts handle extreme temperatures with excellent heat recovery, while maximizing load and torque capacity ― making it one of the most efficient CVT belts currently on the market.

When you go off-road, your vehicle can’t go offline. The next generation of continuously variable transmission (CVT) belts are higher performing and more durable than ever before. Utilizing proprietary design software combined with the most advanced composite materials and construction technology, Gates powersports products are engineered to meet the demands of today’s and tomorrow’s high-performance ATV and UTV’s

WHY G-FORCE™ REDLINE™ CVT BELTS?

Greater heat resistance and recovery, even under severe duty cycles

Optimized, patented EE compound maximizes axial stiffness enabling belts to run at higher continuous torques or loads.

Innovative design results in better acceleration, higher top speeds, less speed ratio and energy loss in extreme off-road environments.

Improved durability, crack and wear-resistance means a longer-lasting, high-performance power transmission belt for the most demanding applications.

Reduced Environmental Risk — made without harmful chlorinated compounds.

FEATURES & BENEFITS

- First on the market to utilize Ethylene Elastomer compound to address the needs of larger SxS and high-horsepower ORVs in tough riding conditions

- Next-generation EE compound offers maximum transverse stiffness and heat resistance, resulting in higher load capacity, higher peak torque capacity, less “heat fade” and less speed loss

- Delivers 75% greater dynamic axial stiffness on average, up to 50% lower speed losses and better recovery from temperatures up to 338°F (170°C) without power loss

- Unmatched Temperature Capability – Runs cooler, resists glazing for better recovery and reduced cracking/chunking out after running at temps exceeding 300°F

- Extended Belt Life – Belt life increased 100-300% versus aftermarket competitive belts in severe duty lab test conditions and in field testing

- Higher Power Capacity – Reduced speed (rpm) loss by 50% under high loads and increased load capacity by >10% compared to other aftermarket belts

INNOVATION FUELED BY MATERIALS SCIENCE:

- Greater heat resistance and recovery, even under severe duty cycles

- Optimized, patented EE compound maximizes axial stiffness enabling belts to run at higher continuous torques or loads

- Innovative design results in better acceleration, higher top speeds, less speed ratio and energy loss in extreme off-road environments

- Improved durability, crack and wear-resistance means a longer-lasting, high-performance power transmission belt for the most demanding applications

- Reduced environmental risk — made without harmful chlorinated compounds

DON’T BREAK YOUR BELT. BREAK IT IN.

If you don’t break the belt in properly, you’ll find yourself shredding the belt instead of the terrain. In fact, most powersports belt failures can be attributed to improper break-in and clutch adjustment – or not breaking in the belt at all. Follow these three steps to ensure the best performance and longest life from your G-Force™ belt.

1. Install the Right Belt. Using a belt that’s even slightly different than OE specifications can affect performance – or stop you in your tracks.

2. Align and Clean. Align the clutches according to manufacturer specifications and clean the sheaves with a Scotch-Brite™ pad. Remove old belt residue, glazing, oils, and debris with alcohol or acetone on the clutch sheave area. DO NOT USE BRAKE CLEANER.

3. Install and Break It In. Perform two heat cycles (10-15 minutes each) at +27°C (+80°F) at 30-40 mph (2-wheel drive) with cover installed. Bring the belt temperature down to normal operating temperatures, then shut down and let cool for 30 minutes. Repeat the process a second time. If belt installation is at a temperature of +16°C (+60°F) or below, perform two heat cycles in 20 minutes at 30-40 mph (2-wheel drive) with cover installed. Bring the belt temperature down to normal operating temperatures, then shut down and let cool for 30 minutes. Repeat the process a second time. Conservatively run through the entire shift range, without exceeding ¾ throttle. Bring the belt back to normal operating temperature (15 minutes) then shut down and completely cool the belt for 30 minutes. Repeat the process.

Break In Video in the Guides/Install Tab

Manuals

All of our products by hand in the U.S.A. We build our parts to withstand the toughest of conditions, as long as they have been installed correctly and have not been modified, altered, improperly installed or otherwise not used as originally intended. We carry a limited guarantee our parts for life to the original purchaser from failures that are due to craftsmanship, material failure or any other factors that are determined to be our responsibility.

Warranty Form And Further Details Located “HERE”

Any In Stock items will be shipped within 24 – 36 hours of order processing Monday through Friday, orders placed on Saturday or Sunday will be processed Monday. Your order confirmation will be updated as soon as shipping is setup.

| Make | Model | Year |

|---|---|---|

| CFMoto Off Road | UFORCE 600 | 2021 UFORCE 600 - 2025 UFORCE 600 |

You may also like…

UTV ACCESSORIES

ATV ACCESSORIES

UTV ACCESSORIES

UTV ACCESSORIES

What others are saying

There are no contributions yet.