Factor 55 Off-Road Flat Winch Shackle Setup, Flatlink Setup

Factor 55 Off-Road Flat Winch Shackle Setup, Flatlink Setup

Factor 55 Off-Road Flat Winch Shackle Setup, Flatlink Setup

From: $152.99 From: $109.99

EVERYTHING IS FREE SHIPPING

As Low As 0% Up To 24 Months, Visit Financing Options!

Vehicle Product Fitment Listed Below

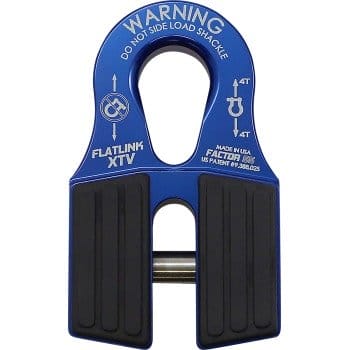

Factor 55 Flatlink Winch Rope Shackel Setup.

A Flat Winch Shackle Setup That Allows You To Replace The Conventional Winch Hook. Secure Screw Pin Attachment. Easy Install. Rubber Guards Protects Fairleads. 6K Lbs. Max Load. 28K+ Lbs. Break Strength.

The FlatLink XTV allows UTV and ATV winch owners to replace the conventional winch hook with a safer and stronger shackle/D-Ring.

Winch hooks can cut and fray recovery straps and often allow strap ends to escape during typical loose/tight cycles of a winching recovery.

Screw pin shackles do not allow strap loops to escape due to the secure screw pin attachment.

The FlatLink XTV does not require splicing and is compatible with steel cables or synthetic ropes up to 5/16 inches.

The cable eye is retained in the FlatLink XTV by a 7/16 inch diameter titanium double shear pin and internal snap ring.

The EPDM Rubber Guards protects alloy fairleads and is securely attached to the FlatLink XTV with 4 barbed tips.

The FlatLink XTV stows neatly against either roller or Hawse type fairleads and is designed to be used with common standard ½ – 5/8 inch shackles.

The FlatLink XTV is constructed of 6000 series billet aluminum and 6Al-4V titanium and is anodized/powder coated in 5 different colors.

It is easily installed in minutes.

Features:

- Precision machined from 6000 series aluminum and 6Al-4V titanium

- Weight – 12.7 ounces

- Fits steel cables and synthetic winch ropes to 5/16 inch diameters

- EPDM Rubber Guard protects alloy fairleads and cushions line stowage

- Simple snap ring removal for shear pin

- Oval hole opening connects to the pin or bow end of ½ or 5/8″ screw pin shackles/D-Rings

- Oval hole opening connects to the pin ends of 3/4″ screw pin shackles/D-Rings

- Stops hook rattle and fairlead damage

- Weight – 12.7 ounces

- Max load rating : 6,000 pounds

- Ultimate failure : 28,000+ pounds

MADE IN THE USA

About Factor 55

Factor 55 products are designed and manufactured using state of the art technologies.

All of our products are designed and then stress analyzed, resulting in us to optimize a design concept by adding or removing material or changing material properties where necessary.

We then validate our theoretical results by instrumenting and destructively testing prototypes of all of our product designs.

This is conducted at a test and measurement facility that is also certified for National Defense Department rigging and hoist testing.

At Factor 55 we don’t believe in engineering compromises. That’s why we produce all of our products from aerospace quality materials.

From 6000 and 7000 series aluminums, to 6AL-4V titanium double shear pins, we strive to offer you the very best designs made from the ve

Add On Option, Rope Guard

For you hardcore off-roaders and off-road trainers, the new Rope Guard provides complete synthetic rope protection from damaging UV light as well as impact and abrasion damage.

When using the Rope Guard, all exposed synthetic rope surfaces are positioned behind the guard and fairlead, allowing you to use the Rope Guard as a skid surface when attempting to climb tall vertical obstacles.

We recommend that the FlatLink first be removed from your winch line prior to the Rope Guard installation. Then, remove all rubber pieces from your FlatLink product. A little prying from a flat blade screwdriver should do the trick in popping out the rubber barbs.

We recommend that you place the FlatLink on top of a piece of wood on the ground or workbench surface prior to hammering in the drive rivets. Be sure to orient the Rope Guard in the correct direction (slot facing the rear) prior to proceeding with the rivet installation. Now simply insert the 4 included drive rivets and using a ¼ inch punch, hammer the drive rivet posts down until the posts are flush with the top of the rivet head. Reinstall the 2 rubber pads (lubricate the barbs) on the opposing side and you are done.

In Stock Items:

Any In Stock items will be shipped within 24-36 hours of order processing Monday through Friday, orders placed on Saturday or Sunday will be processed Monday.

When Your items are Picked Up By The Shipper Our System will Updated and Email You Tracking.

Powder Coated / Custom Colors / Fabrication ORDER PROCESSING

Please allow adequate time for custom fabrication parts to be built, powder coated, and shipped. Currently These Items Are 8-12 Business Days for Production

Lead Times define the maximum estimated amount of time required to prepare the item for shipping and may vary depending on product, volume of current orders, and/or build schedules. This includes fabrication, powder coating, packaging, and other preparation. In the event that Lead Times are delayed you will be contacted via email or phone call.

Lead Times DO NOT include shipping transit times.

All parts will be shipped as soon as possible after the initial Lead Time using your selected shipping method.

| Make | Model | Year |

|---|---|---|

| All Universal Fitment | ATV Machine - Universal Fitment | |

| All Universal Fitment | UTV Machine - Universal Fitment |

You may also like…

ATV PRODUCTS

ATV WINCH

What others are saying

There are no contributions yet.