CT Race Worx Polaris RZR Pro R A Arms, Turbo R A Arms

From: $1,459.99

ALWAYS FREE SHIPPING

As Low As 0% Up To 24 Months, Visit Financing Options!

Vehicle Product Fitment Listed Below

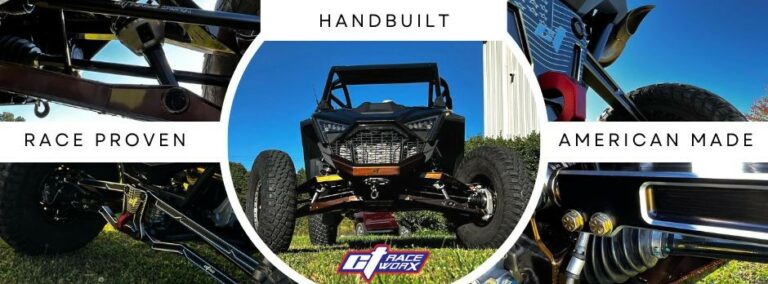

CT Race Worx Boxed A Arms For RZR Pro R And Turbo R Models

The King Of Production Brings You The Strongest Pro R A Arms Around, These Boxed Design Turbo R A Arms Are The Best You Can Purchase And Will Take Any Beating

If you want to add strength and eliminate the lack of trust from ball joints on your Pro R or Turbo R, look no further. The goal was to create an arm that addressed every possible issue and then some and we did just that.

Upgrade your Polaris Pro R with the CT Race Worx Polaris Pro R A Arms and experience unmatched off-road performance.

Engineered with precision and crafted with superior materials, these boxed upper A arms offer exceptional strength and durability.

The boxed design provides increased ground clearance, allowing you to navigate through rugged terrains and conquer obstacles with ease. With optimized suspension geometry, these upper A arms enhance your vehicle’s handling, stability, and control, ensuring a smooth and controlled ride.

Their corrosion-resistant finish ensures long-lasting protection against the elements. Take your off-road adventures to the next level with CT Race Worx Polaris Turbo R A Arms, the perfect upgrade for enthusiasts seeking reliable performance and rugged durability.

As always our a arms have a no BS lifetime warranty. The uniballs and spindle pin do not have a lifetime warranty.

NOTE – If you plan on ordering this part bare and are going to powder coat it, you can NOT let the bore of either uniball (shock or spindle) pocket get sand blasted or powder coated. These parts get machined to an extremely tight tolerance and get measured with a bore gauge, if that does happen, you won’t get the uniballs in straight or the snap rings in the grooves. If this happens we will NOT warranty the item due to improper fitment of the uniballs.

Lower Arms –

The construction off this arm consists of a mix of .115″ and .135″ Grade 50 steel. The front face of the arm has a 45 degree face on the bottom edge so when you hit that rock or obstacle it will help push it up and over, and let us add these arms don’t mind being beat on things, they beg for it. The internal structure of this arm is very unique, it features an I beam style construction that is roughly 13″ long and starts at the uniball cut and run past the shock mount. The shock mount is machined into this chunk of steel and houses a WSSX12T FK uniball with stainless steel spacers. The bushing barrels are created to mimic the factory measurements perfectly, except we added 6mmx1 thread and we include grease fittings for serviceability without having to take the front suspension off to lube the pivot points on the chassis. At the spindle side we changed out the failure ridden factory ball joint for an FK WSSX14T uniball which is the top of the line 7/8″ FK spherical bearing. The uniball is held in a custom uniball cup that we machine here in house from 4130 chromoly. To finish off the spindle side of things the spindle pin is made and heat treated in house from 17-4 stainless to H900 standards and holds the factory geometry and pivot point location perfectly. Steering stops have also been added to the arms in the factory location to keep the outer CV within its tolerances through the suspension travel and steering angles.

Upper Arms –

We started with our boxed a arm design which has be proven for a decade throughout our product line. The brake line bungs in the arm have a sealed bottom, they are not exposed into the internals of the a arm and they utilize 6mm hardware that we supply. The CT logo on top of the arm is cut from stainless steel and can be left bare, polished or powder coated depending on the look you’re going for. The bushing barrels are created to mimic the factory measurements perfectly, except we added 6mmx1 thread and we include grease fittings for serviceability without having to take the front suspension off to lube the pivot points on the chassis. At the spindle side we changed out the factory ball joint for an FK JMX14T-770 joint which is the top of the line 7/8″ FK Rod End. The joint is secured and kept in place by a pinch clamp that we machine here in house made from a block of 4130 chromoly. A 5/16″ Grade 9 bolt squeezes on the threads to make sure it doesn’t move, also this design doesn’t keep you wondering if a jam nut will break loose since there is no jam nut. The joint is threaded in and only leaves about 4 threads exposed, this allows you to add or subtract chamber to your likings or if you’re dealing with a tweaked frame and you’re trying to get your tires upright perfectly again. To finish off the spindle side of things the spindle pin is made and heat treated in house from 17-4 stainless to H900 standards.

Shop More From “CT Race Worx”

Add On Lower Skid Plates

To top things off, we created the ability to add an optional skid plate to the trailing arm. We machined large 10mm sealed bungs and added them along the bottom side of the arm. The skid plates are made from 3/8″ UHMW and have a formed sides going up along the sides to extra protection but also so they won’t get caught on anything. Countersunk 10mm hardware and 7075 aluminum washers retain the skid and leave a perfectly flat bottom to the a arm.

CT Race Worx proudly crafts all of our products by hand in the U.S.A. We build our parts to withstand the toughest of conditions and we believe that factory parts will fail the customer before our parts will, as long as they have been installed correctly and have not been modified, altered, improperly installed or otherwise not used as originally intended. We guarantee our parts for life to the original purchaser from failures that are due to craftsmanship, material failure or any other factors that are determined to be our responsibility.

These Products have became the Industry Leading And Have Been Selling So Fast Times have Been Extended, Items Can Ship Faster But These Are Standard Times:

- Currently A-Arms are shipping about 3-4 weeks after order date. Placing Your order holds Your Place in line and We will ship right off of the production line to you.

- Gusset Kits and Shock Mounts are shipping about 3-4 weeks after order date. Placing Your order holds Your Place in line and We will ship right off of the production line to you.

Normal In-stock or Raw Products

We try to process and ship all products 5-10 Business Days after orders are placed, we only ship Monday – Friday.

Fabricated and or Powered Coating.

Please Allow about 4 weeks to process Fabricated and or Powder Coated Items.

We strive to ship products out sooner than that , and often times next day, but we can not guarantee that with standard, free shipping.

| Make | Model | Year |

|---|---|---|

| Polaris Off Road | RZR Pro R | 2022 RZR Pro R - 2024 RZR Pro R |

| Polaris Off Road | RZR Pro R 4 | 2022 RZR Pro R 4 - 2024 RZR Pro R 4 |

| Polaris Off Road | RZR Pro S | 2025 RZR Pro S |

| Polaris Off Road | RZR Turbo R | 2022 RZR Turbo R - 2024 RZR Turbo R |

| Polaris Off Road | RZR Turbo R 4 | 2022 RZR Turbo R 4 - 2024 RZR Turbo R 4 |

You may also like…

UTV Ball Joints

Related products

UTV Limit Straps

Sandcraft Motorsports Polaris RZR XP 1000 Limit Straps, Full Kit

UTV Limit Straps

Sandcraft Motorsports Textron Wildcat XX Limit Straps, Full Kit

What others are saying

There are no contributions yet.