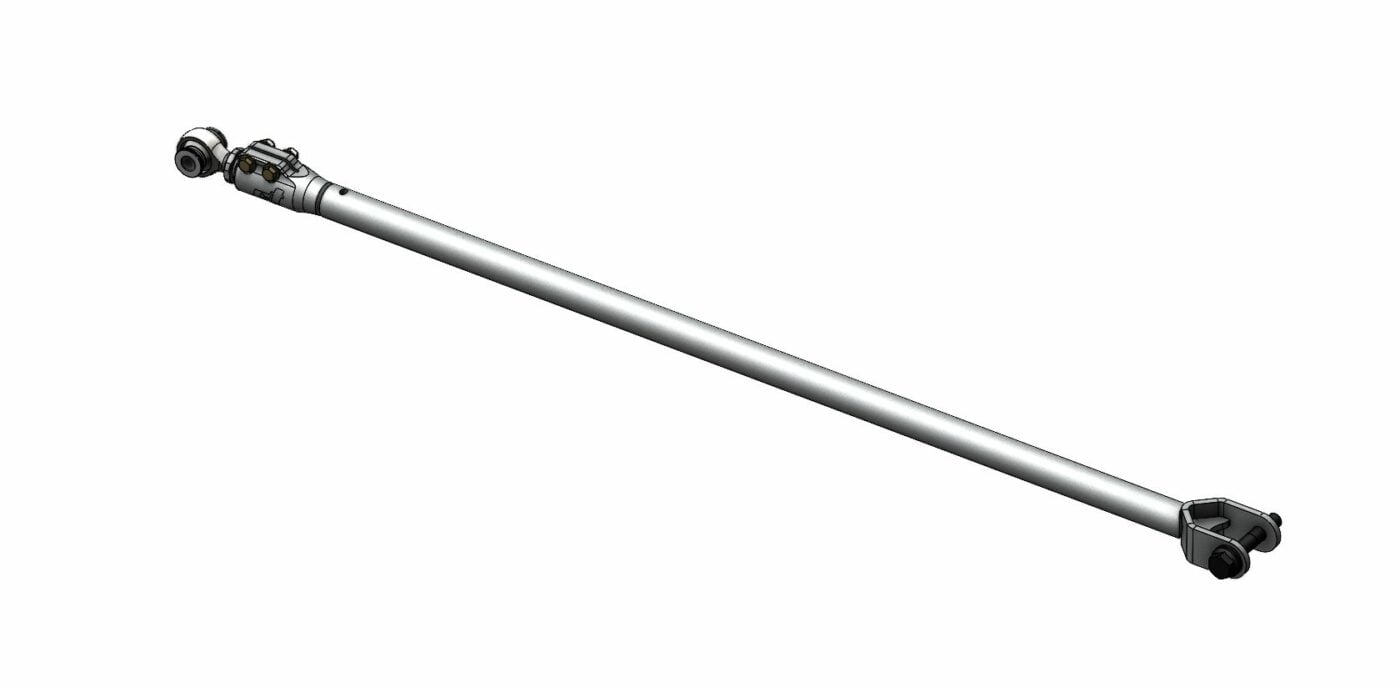

CT Race Worx Polaris RZR Pro R Toe Link Bar, Turbo R Toe Link Bar

From: $1,029.99

ALWAYS FREE SHIPPING

As Low As 0% Up To 24 Months, Visit Financing Options!

Vehicle Product Fitment Listed Below

CT Race Worx Rear Toe Link Bar For Pro R And Turbo R Models

Milled Billed Pro R Rear Pull Hook, This Radius Rod Pull Plate With Tow Hook Increases Strength Out Of Two Different Metals, Shop Turbo R Rear Pull Hooks Now.

The factory Pro R toe links have 2 major issues.

The first issue is the adjuster assembly, which is made of up an eccentric bolt, constantly comes loose and throws the car out of alignment causing handling issues.

The second issue is the material of the toe link is thin and it can’t control the force that the tire is seeing through rough terrain, this is allowing the toe link to deflect inside the trailing arm which isn’t allowing the rear suspension to hold a consistent toe. It creates unusual feedback and odd handling characteristics.

So we set out to correct those issues.

These parts have been ran and are proven at KOH. This item has our lifetime warranty.

NOTE – If you plan on ordering this part bare and are going to powder coat it, you can NOT let the threads on the inside of the adjuster assembly get sand blasted or powder coated. These parts get machined to an extremely tight tolerance and we test every piece after it is made, if that does happen, you won’t get the adjuster back together and it likely will not tighten. If this happens we will NOT warranty the item if it does not function properly.

We started our design process to address the alignment issue in the factory adjuster. At first we thought about doing a traditional link with a right hand thread on one side and a left hand thread on the other with jam nuts. It would have been simple but accessing the spindle side in the trailing arm would have been tough, especially with aftermarket trailing arms. The biggest fear was the jam nuts coming loose due to massive force that the link sees, if you can’t get in to the jam nut to get proper torque you’re going to have problems and if you drag the frame side over a rock and break the jam nut loose you’re not better off than the factory design because the potential for a problem hasn’t been eliminated. So we went a different route altogether.

We created a clevis on the spindle side out of 1/4″ Grade 50 steel with an internal gusset to eliminate deflection, we also threw the idea of the eccentric bolt and a slot in the clevis in the trash and went with a conventional round hole. On the frame side of the toe link we went with our proprietary single point adjuster that doesn’t use any jam nuts. This adjuster is made up of a 3/4″ LH JMX12T rod end, and 2 pieces that we machine here in house. The adjuster collar is made from a piece of 17-4 stainless steel that we heat treat for extra strength, this piece has a 1″ OD right hand thread and also a 3/4″ ID left hand thread and has multiple slots through the thread. The body that houses the adjuster has the 1″ ID thread and has a slot through the body, to tighten it we have (2) 5/16″ grade 9 bolts. To adjust the link, you loosen the (2) 5/16″ bolts and use an 1-1/4″ wrench to turn the adjuster collar. The adjuster collar and joint thread and unthread at the same rate making adjustments as easy as they could possibly be while giving 3/4″ of total adjustment in overall length which is double what the factory allowed for. To tighten everything and secure it in place you torque the (2) 5/16″ bolts to 25 ft lbs and you’re done.

To address the deflection of the rod, our first thought was to go to a piece of 1.25″ .125″ 4130 chromoly. We built our first test set out of this but noticed how much deflection that diameter tubing had over the distance of the link. Since there are constraints to the overall design that don’t allow us to increase the diameter of the tube, we could only increase the wall thickness. This toe link is made from 1.25″ .1875″ wall 4130 chromoly. We went this heavy for 2 reasons, to eliminate the deflection, but also to give piece of mind if the front portion of the toe link was to get smashed on a rock.

Shop More From “CT Race Worx”

CT Race Worx proudly crafts all of our products by hand in the U.S.A. We build our parts to withstand the toughest of conditions and we believe that factory parts will fail the customer before our parts will, as long as they have been installed correctly and have not been modified, altered, improperly installed or otherwise not used as originally intended. We guarantee our parts for life to the original purchaser from failures that are due to craftsmanship, material failure or any other factors that are determined to be our responsibility.

These Products have became the Industry Leading And Have Been Selling So Fast Times have Been Extended, Items Can Ship Faster But These Are Standard Times:

- Currently A-Arms are shipping about 3-4 weeks after order date. Placing Your order holds Your Place in line and We will ship right off of the production line to you.

- Gusset Kits and Shock Mounts are shipping about 3-4 weeks after order date. Placing Your order holds Your Place in line and We will ship right off of the production line to you.

Normal In-stock or Raw Products

We try to process and ship all products 5-10 Business Days after orders are placed, we only ship Monday – Friday.

Fabricated and or Powered Coating.

Please Allow about 4 weeks to process Fabricated and or Powder Coated Items.

We strive to ship products out sooner than that , and often times next day, but we can not guarantee that with standard, free shipping.

| Make | Model | Year |

|---|---|---|

| Polaris Off Road | RZR Pro R | 2022 RZR Pro R - 2024 RZR Pro R |

| Polaris Off Road | RZR Pro R 4 | 2022 RZR Pro R 4 - 2024 RZR Pro R 4 |

| Polaris Off Road | RZR Pro S | 2025 RZR Pro S |

| Polaris Off Road | RZR Turbo R | 2022 RZR Turbo R - 2024 RZR Turbo R |

| Polaris Off Road | RZR Turbo R 4 | 2022 RZR Turbo R 4 - 2024 RZR Turbo R 4 |

You may also like…

UTV Limit Straps

Sandcraft Motorsports Polaris RZR Pro R Limit Straps, Full Kit

Related products

UTV Limit Straps

Sandcraft Motorsports Polaris RZR XP Turbo Limit Straps, Full Kit

UTV Limit Straps

Sandcraft Motorsports Polaris General Limit Straps, Full Kit

UTV A Arm Bushings

Sandcraft Motorsports Can-Am Maverick X3 A Arm Bushings, Sleeve Upgrade Kit

UTV BulkHeads

UTV Limit Straps

Sandcraft Motorsports Polaris RZR XP Turbo S Limit Straps, Full Kit

UTV Limit Straps

Sandcraft Motorsports Polaris RZR XP 1000 Limit Straps, Full Kit

What others are saying

There are no contributions yet.