High Lifter Polaris RZR XP Rebuildable Ball Joints

$128.99

EVERYTHING IS FREE SHIPPING

As Low As 0% Up To 24 Months, Visit Financing Options!

Vehicle Product Fitment Listed Below

In Stock Item (See Below Shipping Tab)

Purchasing Earns $6.45 In Cash Back Rewards

High Lifter APEXX Heavy Duty Ball Joints For Polaris RZR Models

Massive Upgraded RZR XP Rebuildable Ball Joints Are Designed To Last And Also Give You The Ablity To Adjust The Pivot Point And Rebuildable Design

Are you tired of having to carry 2 or 3 extra ball joints on every ride? So were we!

For some riders, replacing busted ball joints has become as common as refueling. If this sounds like you, the APEXX Performance Ball Joint is High Lifter’s answer to your struggle!

By their nature ball joints cannot be made to last forever. There is simply too much friction, wear, and stress they must endure to last a lifetime.

These Fit Turbo R And Pro R Upper Arms Only, See “UTV Ball Joints” For Lower Options

For Small Models, Trails And Sport (900, 1000) See: RZR Rebuildable Ball Joints

Our goal here at High Lifter was to design an option that would last far longer than other ball joints on the market. So we developed the new APEXX Performance Ball Joint.

Polaris Uses The Same Ball Joints On Both Sides, And The Same Upper And Lower Joints. Just Add The Quantity You Need

Features

- 2x Stronger than OEM Ball Joints

- 4340 Chromoly Housing, Bushing, Cap & Stud

- Oversized Sphere and Stud Diameter with Optimized Profile

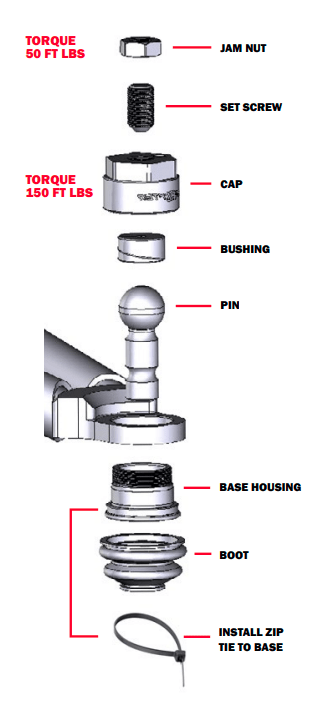

- Fully Serviceable & Rebuildable for Increased Longevity and Reliability

- Strength

Even a brand new and well lubricated ball joint can break under extreme conditions. This is seen more often in OEM ball joints as well as some of the cheaper aftermarket ball joints sold today. They are often made just well enough to be used on a stock vehicle driven under normal riding conditions. Typically designed with smaller shafts and softer metals to reduce cost, they simply will not hold up under the conditions that veteran riders with vehicles running performance enhancing accessories or larger tires put them through. When creating the APEXX Performance Ball Joint, we used 4340 chromoly steel for not only the housing, but also the stud itself. The stud is what bares most of the forces applied to the ball joint, so we designed ours to be thicker and with a design profile that gives maximum relief against load pressure. The housing and stud have also had an attractive black zinc coating applied to them for increased protection against corrosion. All of this together adds up to a ball joint with twice the strength of its OEM counterparts. - Durability

We wanted the ability to add new grease to the ball joint whenever we wanted and rebuild them as the need arose. You see, many if not most of the ball joints that came factory-installed on your vehicle and even many of the aftermarket ball joints have been sealed for life. That is, they cannot be greased or rebuilt. This sounds like a good idea, I mean who likes to perform regular maintenance, right? The problem with sealed-for-life ball joints is the seals and other internal components are often made up of some type of plastic or synthetic, and when plastic is paired against steel parts, you can imagine which will fail first from wear or applied stress. Often, you are not able to tell that your seal has failed, allowing a loss of grease until the ball joint starts popping and then seizes and breaks. When this happens, the only option you have is to replace the ball joint with a new one. Well, that is just not acceptable, so we designed the new APEXX ball joint without these synthetic seals, liners, or bushings. Our design uses all steel on steel parts, allowing for a longer life and providing the ability to be easily rebuilt and greased via a needle zerk fitting. Now, no matter if you are riding in the dunes, mountains, or woods, you’ll have the peace of mind knowing your ball joint has fresh grease and it’s built with the strength to withstand the ride ahead. - Adjustability

As mentioned before, everything can wear down over time. This is especially true for components used on offroad vehicles. No matter how great they are lubricated or how strong they are made, any part that constantly moves and is mated against another part will wear. That’s why our design allows you to easily set the pressure applied against the ball joint stud. This way, any “slack” caused from wear can be removed with a simple turn of the adjustment screw. When the wear becomes too much to be adjusted out, then simply rebuild the ball joint with our ball joint rebuild kit and now you’re as good as new. - Warranty

High Lifter offers a 1-year Limited Warranty to the original purchaser that our product shall be free from defects in material and workmanship for the life of the product if utilized in accordance with the manufacturer’s instructions for installation and operation of said products.

Manuals

APEXX Ball Joint Adjustments

Download DocumentHigh Lifter offers a Limited Lifetime Warranty to the original purchaser that our product shall be free from defects in material and workmanship for the life of the product if utilized in accordance with the manufacturer’s instructions for installation and operation of said products. This Limited Lifetime Warranty extends to the following product lines:

• Lift Kits (Signature, Standard and Big Lifts)

• Control Arms

• Trailing Arms

• Radiator Relocation Kits

• Portal Gear Lifts

• Wheel Spacers

• Tow Hooks

• Control Arm Link Kits

For Complete Warranty Information And Claims Information Please Click “High Lifter Warranty”

IN STOCK PARTS – Any items in current inventory we ship within 36-48 hours after order.

- Portal Gears Can Take Up To 7-10 Business days To Ship After Order because of Assembly.

- Snokel Kits Can Take Up To 7-10 Business days To Ship After Order because of Assembly.

- Pressed In Ball Joint Arm Orders Cake Up To 7-10 Business days To Ship After Order because of Assembly.

We currently only ship Monday through Friday, if you place the order over the weekend we will process it on Monday.

Current Fabrication or Production Run Parts

Currently anything listed on the site is traditionally stocked and ready to ship but there are times that we are currently in a production run and or waiting for powder coating, this could result in 10-14 Business day shipping

Lead Times define the maximum estimated amount of time required to prepare the item for shipping and may vary depending on product, volume of current orders, and/or build schedules. This includes fabrication, powder coating, packaging, and other preparation. In the event that Lead Times are delayed you will be contacted via email or phone call.

Lead Times DO NOT include shipping transit times.

All parts will be shipped as soon as possible after the initial Lead Time using your selected shipping method.

| Make | Model | Year |

|---|---|---|

| Polaris Off Road | RZR Pro R | 2022 RZR Pro R - 2026 RZR Pro R |

| Polaris Off Road | RZR Pro R 4 | 2022 RZR Pro R 4 - 2026 RZR Pro R 4 |

| Polaris Off Road | RZR Pro S | 2025 RZR Pro S - 2026 RZR Pro S |

| Polaris Off Road | RZR Pro S 4 | 2025 RZR Pro S 4 - 2026 RZR Pro S 4 |

| Polaris Off Road | RZR Pro XP | 2020 RZR Pro XP - 2026 RZR Pro XP |

| Polaris Off Road | RZR Pro XP 4 | 2020 RZR Pro XP 4 - 2026 RZR Pro XP 4 |

| Polaris Off Road | RZR RS1 | 2018 RZR RS1 - 2022 RZR RS1 |

| Polaris Off Road | RZR Turbo R | 2022 RZR Turbo R - 2024 RZR Turbo R |

| Polaris Off Road | RZR Turbo R 4 | 2022 RZR Turbo R 4 - 2024 RZR Turbo R 4 |

| Polaris Off Road | RZR XP 1000 | 2014 RZR XP 1000 - 2026 RZR XP 1000 |

| Polaris Off Road | RZR XP 1000 EPS LE | 2014 RZR XP 1000 EPS LE - 2017 RZR XP 1000 EPS LE |

| Polaris Off Road | RZR XP 1000 High Lifter | 2017 RZR XP 1000 High Lifter - 2022 RZR XP 1000 High Lifter |

| Polaris Off Road | RZR XP 1000 Ride Command | 2018 RZR XP 1000 Ride Command |

| Polaris Off Road | RZR XP 1000 Rocks and Trails | 2018 RZR XP 1000 Rocks and Trails - 2022 RZR XP 1000 Rocks and Trails |

| Polaris Off Road | RZR XP 4 1000 | 2014 RZR XP 4 1000 - 2026 RZR XP 4 1000 |

| Polaris Off Road | RZR XP 4 1000 High Lifter | 2016 RZR XP 4 1000 High Lifter - 2021 RZR XP 4 1000 High Lifter |

| Polaris Off Road | RZR XP 4 Turbo | 2017 RZR XP 4 Turbo - 2021 RZR XP 4 Turbo |

| Polaris Off Road | RZR XP 4 Turbo Dynamix | 2018 RZR XP 4 Turbo Dynamix - 2019 RZR XP 4 Turbo Dynamix |

| Polaris Off Road | RZR XP 4 Turbo S | 2019 RZR XP 4 Turbo S - 2021 RZR XP 4 Turbo S |

| Polaris Off Road | RZR XP 4 Turbo S Velocity | 2020 RZR XP 4 Turbo S Velocity - 2021 RZR XP 4 Turbo S Velocity |

| Polaris Off Road | RZR XP S 1000 | 2026 RZR XP S 1000 |

| Polaris Off Road | RZR XP S 4 1000 | 2026 RZR XP S 4 1000 |

| Polaris Off Road | RZR XP Turbo | 2016 RZR XP Turbo - 2021 RZR XP Turbo |

| Polaris Off Road | RZR XP Turbo Dynamix | 2018 RZR XP Turbo Dynamix - 2019 RZR XP Turbo Dynamix |

| Polaris Off Road | RZR XP Turbo Fox Edition | 2018 RZR XP Turbo Fox Edition |

| Polaris Off Road | RZR XP Turbo S | 2018 RZR XP Turbo S - 2021 RZR XP Turbo S |

| Polaris Off Road | RZR XP Turbo S Velocity | 2019 RZR XP Turbo S Velocity - 2021 RZR XP Turbo S Velocity |

You may also like…

UTV ACCESSORIES

UTV Filters

ATV Fluids

What others are saying

There are no contributions yet.